Discover Starch Solutions from Tate & Lyle

Explore the World of Starches

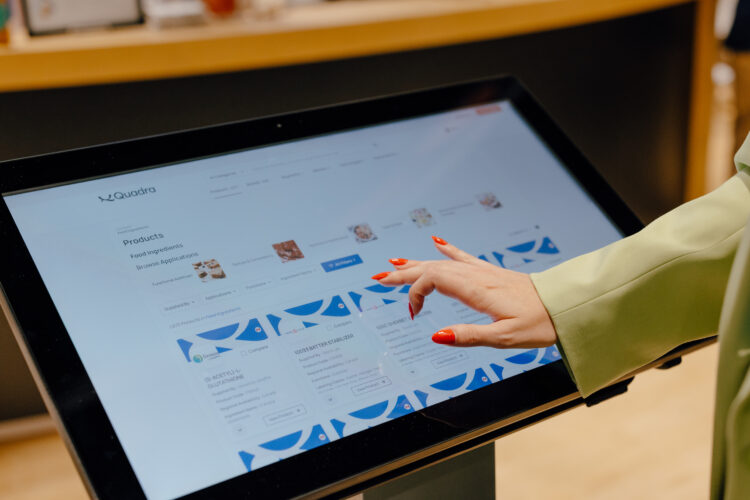

Choosing the right starch is an integral part to product formulation across a variety of applications. It’s important to know the desired texture, taste, and mouthfeel when choosing which starch to include in your product’s formulation. That’s why at Quadra, we carry a vast range of Tate & Lyle starches that are meant to be versatile and allow customization during the product development process. Tate & Lyle’s starches are derived from corn, potato and tapioca, allowing each to play unique roles in a new product’s formula.

Starches play an important role in product development. They are the reason your product can thicken, gel, emulsify, and bulk. Without the right starch, product development can be challenging and even sometimes seem impossible. Quadra’s range of Tate & Lyle starches are perfect for a variety of applications. Whether you are looking to formulate the next best beverage, sweet chocolate truffle, creamy dairy-based yoghurt, crispy cracker, or shelf-stable sauce and dressing, starches have key roles in every one of these applications.

Explore Quadra’s Range of Starches

Starches in Bakery Applications

Tate & Lyle’s starch portfolio allows for baking applications to reach their desired taste, texture, and mouthfeel. If your main priority when formulating is to improve viscosity through bake-stable starches or to provide hydration for thickening with limited water, there are a variety of starch solutions specific to help manage these aspects of the baking process. If texture development is your main concern, such as maximizing the creaminess of frostings and glazes or to control aeration and crumb texture for gluten-free baked goods, Quadra’s team can match you with the right solution. Furthermore, if you are looking to improve moisture retention to extend shelf-life for in-store bakery products or to maximize your frozen product’s freeze-thaw stability for improving appeal and quality, or to provide Clean Label starch solutions for a variety of bakery applications, Tate & Lyle’s starches are a perfect option for you to explore!

Formulating the Perfect Confections

Starches play an important role in confectionary product development. To achieve your desired smoothness, creaminess, chewiness and sweetness for your next indulgent confection, there are so many ways starches can create your desired result. The confectionary market has been growing in recent years with the introduction of new and innovative textures, shapes, and taste profiles for a diverse group of consumers. Along with this growing need for innovation comes the need to produce confectionary products that deliver that guarantee of a sweet and satisfying treat. Whether you need thin-boiling, low-temperature, or cold-swelling solutions to improve viscosity development, starches are essential to achieving these outcomes. From gelling and molding to dusting and setting for achieving process efficiencies, Tate & Lyle’s starch range includes a variety of options to choose from. Lastly, if your main concern is to improve viscosity during handling for depositing and shape formation, there are many cold-flow control starches to choose from that can maximize finished product stabilization.

Making Delectable Dairy Products

Product development for dairy and dairy alternative products continues to be steady, as consumers are constantly looking to be satisfied by nutritious and appealing food products. Tate & Lyle’s starches can help in achieving the desired texture development, whether the need is gelling for yoghurts and dips, creaminess for sauces and puddings, structure for processed cheeses, or mouthfeel improvement to maintain creamy and highly indulgent textures in various dairy or dairy alternative applications. Starches can also help with process functionality by providing a stable solution for pasteurization, high-pressure or heat conditions. Another important aspect to the product development process is controlling ice-crystal growth, melting characteristics and moisture management, which are all elements that starches can aid in controlling. Whether your temperature processing is high or cold, the right starch is critical to achieving optimal product quality. Quadra’s team of technical experts can assist in guiding you through the selection and product development process for dairy and dairy alternative applications.

Starches for Snacking

Consumers continue to include snacking in their everyday routines. Snacks are versatile in flavor, color, shape, format, and appeal. Tate & Lyle’s starch options are derived from a variety of botanical food sources and are available in native, modified, cook-up, instant, and clean label varieties to help you achieve the perfect texture and mouthfeel for your savory or sweet snack product. Texture development is key for snack product development. From increasing expansion, to producing crispy bites, to making sure coatings remain light and crunchy, starches play a key role in all desired texture functions. Process functionality is also a huge key to making sure snacks have proper dough binding, fat reduction, and can be efficient in the manufacturing process. Snacks are versatile and diverse, along with the consumers who enjoy them—Tate & Lyle’s starches provide the ability to customize desired and unique snack applications that appeal to consumers’ taste buds and cravings.

Making Soups, Sauces & Dressings Easier

The soups, sauces and dressings category has many complexities, from taste, texture, and mouthfeel to color and flavor. Creativity can flourish when developing in these categories, however it is important to succeed in the base of the formula before adding in the extra details that make these applications stand out to consumers. It is important to grasp viscosity expectations, such as heat processing for soups and ready-made meals, or cold processing for applications such as salad dressings and microwavable sauces. Starches are key drivers to achieving desired viscosity claims in soups, sauces, and dressings. Not only that, but starches also provide the ability to reach desire texture claims such as gelling in dressings and dips, pulpiness in soups, and overall mouthfeel improvements by reducing fat content without compromising on the creamy and highly indulgent textures consumers crave for. Starches are also key solutions to reach heat and shear tolerance and emulsification levels that are very important in product development. Quadra has a dedicated team of experts for the soups, sauces and dressings category that can aid in selecting the right starch for your next product.